Sample Splitter

Specification:

Designed for the reduction of test samples which are too large in

volume to be conveniently handled. It handles any material from

Sand sizes up to dia. 108 mm. Each Chute bar is 12 mm wide so

that openings of 12-24-36-48-60-72-84-96-108 mm are

possible. Supplied complete with two collecting pans. Clam shell

hopper: 30 litres capacity. Very sturdily constructed, it is totally

Cadmium Plated for rust protection.

Dorry Abrasion Testing Machine

Specification:

It consists of a disc rotating about a shaft connected to a

reduction gear box coupled to a motor. The disc rotates at 28-30

RPM.

Under the rotating disc is a tray with an outlet to facilitate the

removal of sand. Two Conical Hoppers are mounted on a

bracket fixed to the circular tray. An arrangement is made for start

and stop the flow of sand. Two containers with weights are

supplied to keep the specimens pressed against the rotating disc.

Suitable for operation on 220 V, 50 cycles, A.C. Supply

Digital Los Angles Abrasion Testing Machine

Specification:

The machine consists of an electronic control unit and a rolled steel drum

having an inside diameter of 711 mm and internal length of 508 mm. The

drum is rotated at a speed of 31-33 r.p.m. The internal shelf provided with

the machine confirms to ASTM, AASHTO and EN standards. The machine

is equipped with an automatic counter, when the preset revolution count is

reached, the machine will stop automatically. The drum is equipped with

an interlock device which allows the operator to lock the drum into position

for easy loading/unloading of the sample. Power consumption: 750 W

Skid Resistance and Friction Tester Standard

Specification:

Used for the measurement of surface friction properties, the

apparatus is suitable for both site and laboratory applications and

for polished stone value tests using curved specimens from

accelerated polishing tests. The equipment is supplied with:

Additional scale for tests on polished stone value specimens

6 rubber sliders for site use, complete with conformity certificate

Thermometer -10 to +110°c for surface temperature

measurement

1 litre washing bottle, for surface wetting

Tool set with case, for machine assembly

Rule for sliding length verification

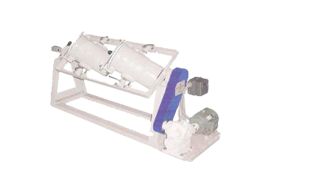

Los Angeles Abrasion Testing Machine

Specification:

The machine consists of a hollow cylinder mounted horizontally on

a study frame on ball bearings. There is an opening which can be

closed with a dust tight cover to facilitate charging and

discharging the drum with the material under test. A detachable

shelf which extends throughout the inside length of the drum which

catches the abrasive charge and does not allow it to fall on the

cover. The drum is rotated by an electric motor through a heavy

reduction gear at a speed of 30-33 R.P.M. A revolution counter is

fitted to the frame. A tray is supplied for collection of the material at

the end of the test. Complete with Abrasive Charge consisting of a

set of Twelve hardened steel balls, approximately 48mm dia.

Suitable for operation on 440 V, 3 Phase, 50 cycles, A.C. Supply.

Aggregate Impact Tester with Blow Counter

Specification:

The instrument consists of a circular base with Two vertical guides.

The Hammer of weight 13.75 +/-0.25kg can be raised to fall

freely down the vertical guides. The Height of fall can be adjusted

through 380 +/- 5mm. The Hammer is provided with a locking

arrangement.

The hammer falls freely to the base and is removable for

employing. Supplied complete with metal measure 75mm dia x

50mm high

(For specimen preparation) and Tamping Rod 230mm long x

10mm diameter.

A Blow Counter to count the number of strokes is fitted on top of the

equipment.

Devel Attrition Tester

Specification:

It consists of two hollow cylinders closed at one end and provided

with Fitting covers at the either end. These cylinders are mounted

an a shaft at angle of 300 with the axis of rotation of the shaft. The

shaft rotates at 30-33 RPM. Through a reduction gear operated by

a motor and is provided with a revolution counter. Complete with

Abrasive Charge consisting of 12 Nos. Hardened steel Balls of

48mm dia. Suitable for operation on 440 Volts, Three Phase, 50

Cycles, A.C. supply.

Jaw Crusher

Specification:

Compact and rugged for laboratory and small production units

Designed for speed crushing

Discharge opening adjustment range: 3 - 10mm

Manganese steel jaws adjustable up to 6 mm opening

250 kg materials can be crushed in approx eight hours

Supported with strong steel frame

Voltage: 440 V, Three Phase A.C. Supply

Pulveriser

Specification:

Designed for grinding materials to produce fine mesh samples Ideal for

Self contained grinder with a rotating disc having planetary movement in

vertical plane.

Reduces about 450g quartz type material to 100 mesh in one minute

Dia. of grinding wheel: 175mm

Material of grinding wheel: High Carbon Steel having 53-60 HRC

hardness

Input of material:

used in Cement and Chemical Industries

Tile Abrasion Testing Machine

Specification:

This is used for determination of resistance to wear for Cement &

Concrete flooring tiles. Tiles specimen of size 7.06 cm x 7.06 cm is

pressed face-wise under specific load on a grinding path and

abrasive powder is evenly spread on the rotating grinding disc the

second parallel side of the tile is subjected to wear for similar

number of rotations. The wear of the tile is measured on a thickness

gauge specifically made for the purpose. The machine consists of

a disc rotating at a speed of 30 R.P.M. in a circular tray. A bracket

is provided to hold the specimen. A counter balance lever loads

the specimen. Load applied is 30 Kgf. A funnel is fitted to evenly

spread abrasive powder on the grinding path. A Pre-set Counter

automatically stops the machine after 22 revolutions. This counter

is Re-adjustable. The machine works on 440 V A.C. Three Phase

electrical supply. On request machine to operate on 230 V A.C.

Supply can also be supplied.

Accelerated Polishing Machine

Specification:

High ground steel main spindle running in precision sealed ball bearings

additionally protected by a labyrinth seal spindle axially loaded to eliminate

end play

Adjustable 3 phase motor speed control with adjustable timing belt drive,

reducing power consumption and improves control

Inverter drive to motor for precise speed control

Digital display preset timer and revolution counter

Robust welded steel mainframe, standing on adjustable pads

Specimens manufactured and easily removed from precision machined moulds

14 Specimens located on ‘Road Wheel’ by rubber rings and held by simple

side fixing

Water gravity fed from high level tank through calibrated flow meter

Used abrasive and water collected in easily removable tray

Loaded tyre raised and lowered to the running surface by mechanical lifting

device

Protection by covers and guards may be easily removed for maintenance